Some Known Factual Statements About Mhs - Material Handling Supply Inc.

Some Known Factual Statements About Mhs - Material Handling Supply Inc.

Blog Article

The Basic Principles Of Mhs - Material Handling Supply Inc.

Table of ContentsFascination About Mhs - Material Handling Supply Inc.An Unbiased View of Mhs - Material Handling Supply Inc.Mhs - Material Handling Supply Inc. Fundamentals ExplainedThe Main Principles Of Mhs - Material Handling Supply Inc. The smart Trick of Mhs - Material Handling Supply Inc. That Nobody is Talking About3 Simple Techniques For Mhs - Material Handling Supply Inc.

This line is called the line of activity. forklift rental athens, ga. If the base of this line goes beyond the stability triangular due to the fact that a tons is too heavy or too expensive, or since the forklift is not on a level surface it will tip over. A vertical line prolonging from the center of mass of the vehicle-load combination should stay inside the stability triangular to avoid the forklift from tippingThis stability triangular is made by linking both front wheels and the pivot point of the rear axle. The various other concept to recognize is the forklifts facility of gravity. Notice that the front and back sides of the stability triangle are high-lighted. When unloaded, the forklifts facility of gravity is ideal concerning here.

Heavier lots shift the facility of gravity forward also better. Raising the load also changes the center of mass ahead. In order to avoid the lift from tipping, the consolidated facility of gravity of the tons and the lift have to remain inside the stability triangle (at ground degree) at all times.

Examine This Report about Mhs - Material Handling Supply Inc.

If you have a well balanced tons, the tons is unlikely to impact the side-to-side facility of gravity. https://www.tripadvisor.in/Profile/mhsinc30677. If you drive on a sloped surface, your center of gravity might pass outside of the stability triangle and the lift can tip. Every forklift has an identification plate that notes important information regarding the truck

To ensure that the center of mass of your forklift remains inside the stability triangle, don't try to raise anything heavier than the recognition plate allows. Despite how active you are, you should check your forklift prior to using it. If you do find something that might affect the safety of the lorry you should report it instantly.

Comply with the operators guidebooks provided by the equipment maker. These manuals explain the secure procedure and upkeep of forklifts. Bear in mind, the operator is in charge of the secure procedure of the forklift. Do a pre-operation examination prior to every shift. If the forklift is used all the time, evaluate it either before each shift or after each change.

Mhs - Material Handling Supply Inc. for Beginners

It is finished in two parts: the walk-around inspection, and, the seated assessment. It's a great idea to have a list to make sure you do not miss out on any actions.

If the forklift is an outside forklift with pneumatically-driven tires, inspect the air stress and look for extreme wear on the tires. A tire with reduced air stress can create the lift to tip when a lots is elevated.

See This Report on Mhs - Material Handling Supply Inc.

Look for splits or various other indications of wear. Check all fluid degrees. Inspect the engine for any indicators of wear, loosened connections, or leaks. Clean up any type of excessive oil or other flammable material. Try to find find this cracks or defects in the forks, back-rest, mast, and overhead guard. Inspect the identification plate to ensure it is undamaged and clear.

Always begin the engine while seated in the driver's positionnever while standing together with the forklift. Check all gauges and advising lights, and the battery or gas level. Raise and reduce the forks, and tilt the mast.

Everything about Mhs - Material Handling Supply Inc.

Check the brakes by depressing the brake pedal. Examine the steering. Relocate the forklift onward a few feet.

Look for stimulates or fires coming out of the exhaust system. If you discover anything incorrect with the forklift during the walk-around or seated assessment, do not run it till it has actually been fixed.

Mhs - Material Handling Supply Inc. Things To Know Before You Buy

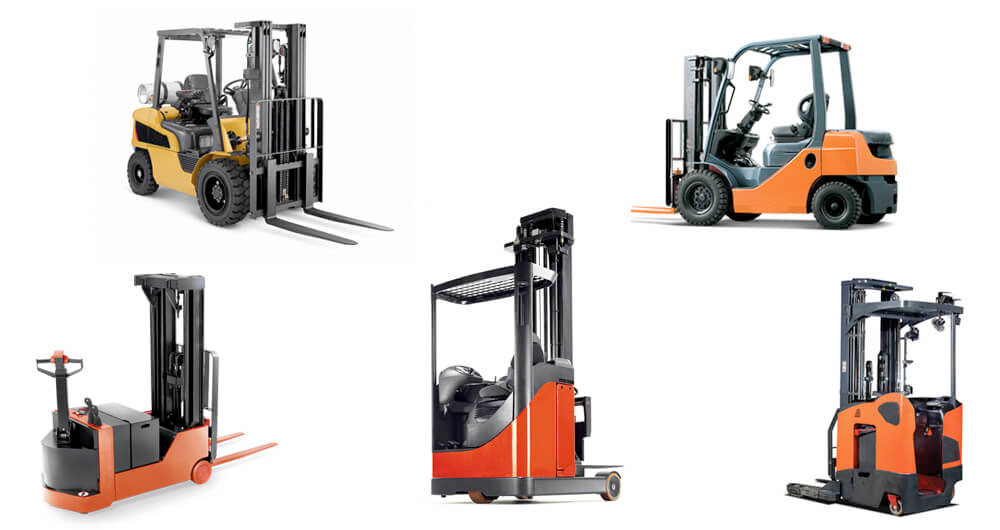

Forklifts have numerous relocating parts and pieces that enable the forklift to run correctly. Understanding the terminology of the parts and makeup of a forklift is very important for efficient interaction with others while on duty - https://dzone.com/users/5134352/mhsinc30677.html. Right here are some of the basic functions and parts that make up the composition of a forklift vehicle

For many forklifts, the pole is made towards the front of a forklift and straight in the forklift driver's field of vision. Forklift masts feature various sections that raise or reduced the forklift carriage in addition to the forks. These consist of:: 2 mast phases: Three pole stages: Four mast sections When selecting a forklift, it is necessary to acquaint on your own with the various functions and terms of a forklift pole: the pole's lift elevation, the totally free lift height and the prolonged elevation and the decreased height.

Report this page